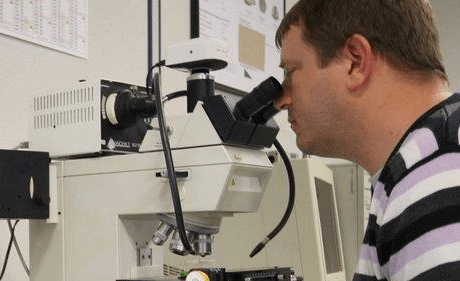

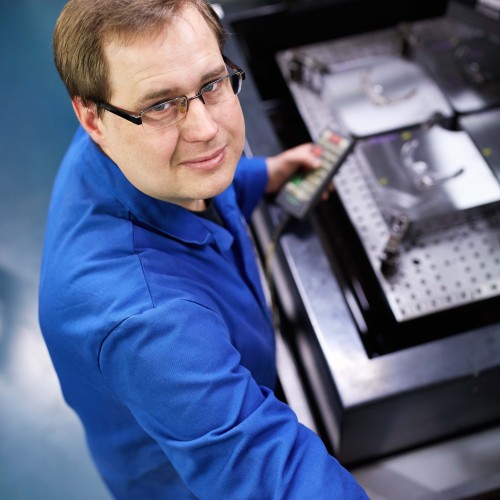

Aluminium

Our aluminium alloys meet weight reduction goals. They also offer good mechanical and physical characteristics and are equally hard wearing.

Brass

Copper alloys developed for automotive applications have as their dominant quality, excellent hard wearing resistance and high level mechanical and physical characteristics. Used in the 'shift forks for gearbox' applications, this dispenses with the need for anti-wear coatings or pad moldings.