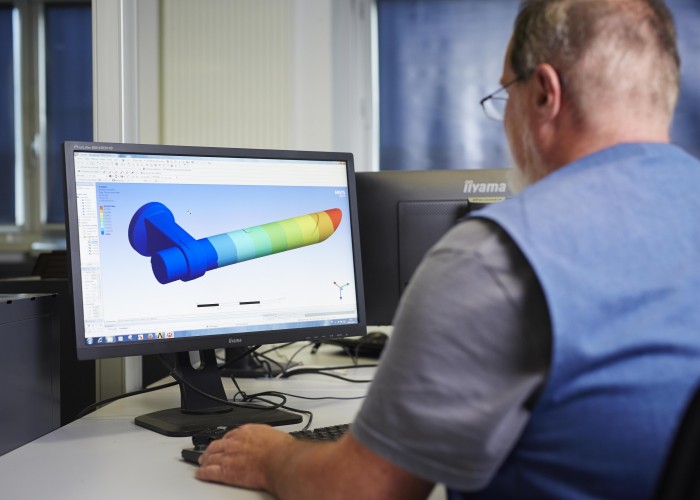

Our know-how in Research & Development, product optimization and validation, allows us to provide optimized, reliable and robust technical solutions.

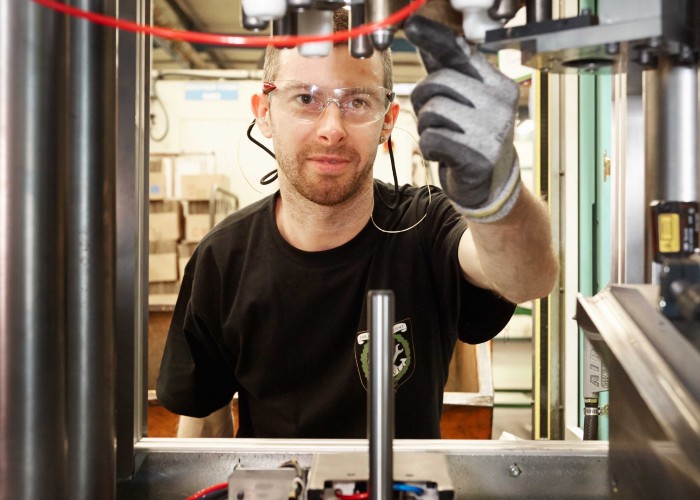

We have a business expertise in pressure die casting, machining and assembling.

Our industrial process adapts to your needs : it allows us to satisfy the mass production requirements and also to provide the appropriate flexibility required by small and mid volumes production.

The Quality, Security, Environment and Energy Policy is an integral part of our corporate culture and our development strategy.