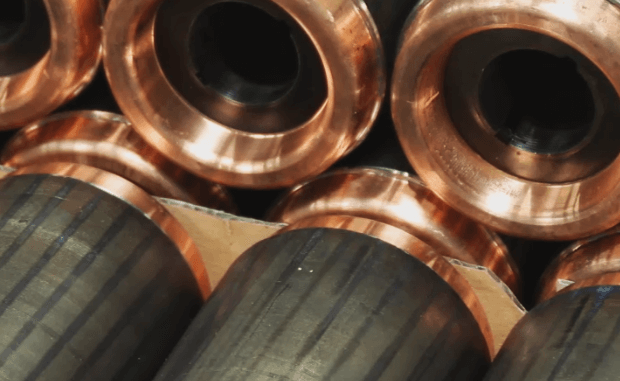

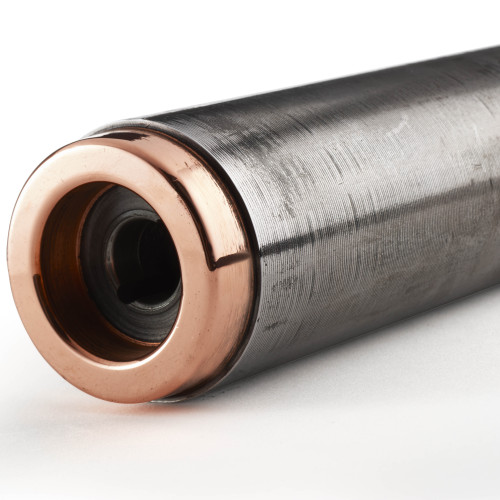

FAVI, specialized in pressure die casting, delivers from Hallencourt (80490), France. Its customers are some of the most renowned groups in the Automotive, Water, Electrical, Aeronautic, Lock and Sanitary industries.

Our requirements in terms of product quality , of People health and safety, come with a strong commitment to sustainable development. Thus , we continually strive to reduce our environmental impact : reducing our water and energy consumption, processing our waste water and industrial pollution, recycling all raw materials etc ...

This commitment is based on The Quality, Safety, Environment and Energy Management standard (QSEE).

60

years experience

400

employees

45%

Export turnover

The FAVI team express their points of view

At FAVI, our staff remains the most important element in our international success story.

As a contemporary company, FAVI offers each employee the opportunity to be responsible for his/her own progress and success.

Team spirit, autonomy are vectors of individual and collective success.

The constant importance that we attach to communication and exchange with our customers is our prime objective.

-

"It's a real pleasure to work at FAVI, which helped me to access professional training and had the confidence in me to manage a production line."

Emilie - CNC machine operator

-

"We can freely express ourselves to help improve our working conditions. FAVI’s bonus scheme is a very positive element.”

Vincent - Tool fitter

-

"I enjoy the autonomy granted by FAVI and the taking into account of our ideas for improvement.”

Ludovic - Lathe tool operator

-

"I appreciate the responsibilities that I am given in the foundry and the sense of cohesion and authenticity in my work zone”

Gérald - Foundry operator

FAVI's goals and quality standards

0

ISO 9001

IATF 16949

FAVI history

2002

FAVI, the first French company to be QSE certified

2000

FAVI, the first French company to be OHSAS 18001 certified

1997

FAVI, the first European foundry to be ISO14001 certified

1974

FAVI builds new factory, becoming one of the European leaders in water meter housings’ production.

1971

Take-over of FAVI by AFICA, Europe’s leading copper alloy refiner and creation of new alloys.

1957

Founding of FAVI :

Subcontracting copper alloys and pressure die-casting. Leader in sanitary fittings’ production (U-bends, floor drains…).

Our management

FAVI, led by its former Director Jean-François Zobrist, developed in the 80’s a CUSTOMER focused organization where the structure fades to assure full listening of the autonomous and responsible teams. An unusual management that promotes a constant search for Customer Love, trust in human being and innovation.