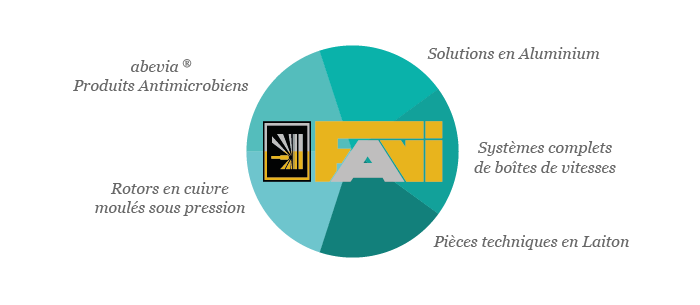

Présentation de FAVI

Basée à Hallencourt, non loin de la Baie de Somme. FAVI est une PME familiale de 300 collaborateurs, spécialisée dans le développement et la production de solutions techniques usinées et assemblées en fonderie sous pression Laiton, Aluminium et Cuivre. FAVI se divise en 5 segments: les solutions en Aluminium, les pièces techniques en Laiton, les rotors en Cuivre moulés sous pression, les systèmes complets de changement de vitesses et transmission, ainsi que la gamme ABEVIA proposant des solutions antimicrobiennes.